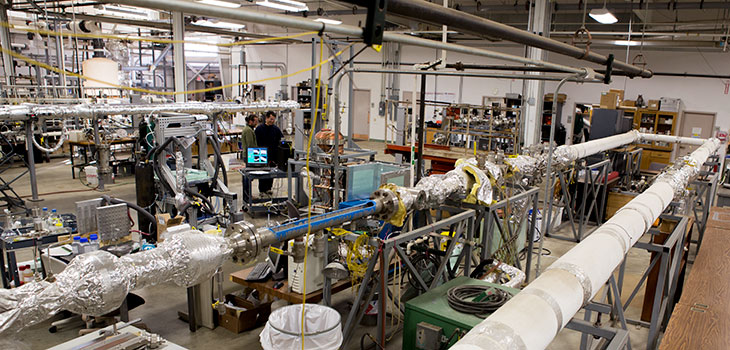

About Our Corrosion Facilities

Ohio University boasts the largest research facility of its kind in the world, and its expertise is sought from all corners of the globe. What is unique about the facility is its size, complete circuits of pipe, and the number of flow loops. The Institute has seven loops that are ideal for long-term projects and enable researchers to deal with a wide variety of research requests from places as disparate as Australia, Oman, Uzbekistan, and Vietnam. Companies pay from $40,000 to hundreds of thousands of dollars every year to be privy to the results of the Institute’s research. They hope to learn how to predict and prevent corrosion so they can repair pipelines before leaks spring on the ocean floor, damaging the environment and costing millions of dollars in lost production. The work done by Ohio University also provides oil companies with information that can help them build oil and gas pipelines with more confidence in remote and previously inaccessible locations.

The ICMT’s test equipment includes:

- A 60-foot long, 4” internal diameter (ID), high pressure/high temperature (HP/HT) flow loop operable at any inclination between 0 and 90 degrees that allows simulation of corrosion in multiphase flow over any type of terrain

- Low pressure/low temperature (LP/LT), “three-phase” (gas/oil/water) re-circulating systems equipped with state of the art phase separation and identification capabilities

- A horizontal, 4” ID, HP/HT, hydrogen sulfide corrosion/multiphase flow system in which a mixture of nitrogen, carbon dioxide and hydrogen sulfide flows together with water or oil in a wide spectrum of multiphase flow conditions

- Two horizontal, 4” ID, HP/HT, corrosion flow loops specifically designed for the study of wet gas transport under dewing (condensation) conditions

- Several LP/LT flow systems, up to 6” ID, dedicated to multiphase flow-related research

- Single and multiphase flow systems designed to simulate high temperature and high-velocity conditions encountered in refinery processing units

- A HP/HT thin channel flow cell to study corrosion in supercritical CO2.

- A dozen autoclaves of various sizes, fully equipped for electrochemical investigation of CO2 (in some cases H2S/SO2) corrosion under flow and up to supercritical conditions

- Several smaller laboratories conducting bench-scale experiments in support of the institute’s industrial-scale work and as a testbed for potential new projects

The ICMT also houses analytical instrumentation including scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), surface profilometry, and a comprehensive range of electrochemical techniques.

Learn More About Our Facilities

H2S Multiphase corrosion flow loop

Inclinable three-phase corrosion flow rig